Precision Zvikamu

-

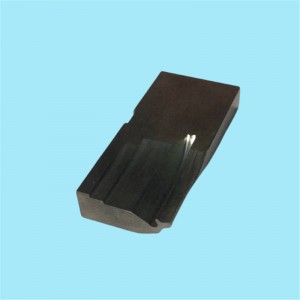

CNC Precision Yakagadzirwa Stainless Simbi Zvikamu

Chii chinonzi CNC precision machining uye chinoshanda sei?

Iyo CNC machining process inoshandisa yakasimba block yezvinhu zvakaita sendarira, mhangura kana simbi.Ichishandisa maturusi anodzorwa nenhamba, inoburitsa nemazvo uye nemazvo zvikamu kune mwero wepamusoro.Lathes, mill, routers, uye grinders maturusi anowanzo kuwanikwa muCNC muchina.Iyo template yedhijitari uye yakazvimirira machining inobvisa kukanganisa kwevanhu uye kuwana chokwadi mukati me1/1000th.

Muchina weCNC wakarongwa nemushandi zvichibva pane zvakatarwa mumifananidzo yeCAD.Iyo programming process inogadzira kodhi iyo inodzora muchina kuburitsa yaunoda yapera chigadzirwa.A test run inopedzwa kuona kuti hapana zvikanganiso mukuronga.Uyu muyedzo unomhanya, unodaidzwa kuti 'kutema mweya' wakakosha mukugadzira zvikamu zvemhando yepamusoro zvakapedzwa uye zvinobvisa zvakanyanya kutambisa zvinhu uye nguva isina basa.Ichi chirongwa chinogona kuzoshandiswa zvadzokororwa kugadzira akawanda mayunifomu zvigadzirwa, zvese zveCNC zvinobuda zvinoenderana neiyo prototype chaiyo yakatarwa.

Kushandisa CNC muchina zvakare kukurumidza zvakanyanya kupfuura kwakajairwa machining, ichipa inodhura-inoshanda sevhisi nekukurumidza kutendeuka-kutenderera.

-

CNC Tsika Yakanyanya Precision Metal Zvikamu

Chii chinonzi High Precision Parts?

High precision chikamu kana machining chaiwo anogona kugara achionekwa kana zvasvika pakugadzira, kugadzira michina, zvikamu, zvishandiso uye nezvimwe. Saka, ndezvipi chaizvo izvo, nei tichizvida kune purojekiti yekugadzira.

Yakanyanya kurongeka zvikamu kana kunyatso machining zviri kureva zvikamu zvine kushivirira kune imwechete digit micrometer.Muchina wakagadzirwa nezvinhu zvakawanda zvihombe nezvidiki, uye kana zvikamu zvese zvisina saizi chaiyo, hazvigone kubatana zvakasimba uye kushanda nemazvo.Kuti muchina ukwane pamwe chete zvakasimba uye uve nekuita kunoenderana, vanogadzira muchina vanowana chaiyo chikamu chinopa chinovapa icho chaicho chikamu chavanoda.

-

CNC Tsika Yakanyanya Precision Mechanical Zvikamu

Nzira Yokudhirowa Cnc Machined Chikamu Kudhirowa?

Ongorora Zvikamu Uye Sarudza Matauriro

Usati wadhirowa, unofanirwa kutanga wanzwisisa zita, basa rechikamu, chinzvimbo chayo mumushini kana chikamu, uye hukama hwekubatana kwegungano.Pasi pechigadziro chekujekesa chimiro chechikamu, musanganiswa nenzvimbo yekushanda uye chinzvimbo chekugadzira, tarisa kuti ndeipi yemhando ina dzezvikamu zvakajairwa zvinotsanangurwa pamusoro (zvose bushings, disks, forks uye mabhokisi), uyezve maererano neKuratidza. maitiro ezvikamu zvakafanana, sarudza chirongwa chakakodzera chekutaura.

-

Tsika Pamhepo CNC Yakagadzirwa Nesimbi Zvikamu

OEM Zvikamu Machining masevhisi Kuvimbisa Yepamusoro-Unhu Hwakagadziridzwa OEM Zvikamu

LongPan yave yakavimbika OEM zvikamu CNC machining masevhisi kambani muChina.Isu tinopa huwandu hwakakwana hweOEM Zvikamu machining masevhisi, ayo anotibatsira siyana zviri nyore kune zvakaoma zvinodikanwa panguva dzinokurumidza kutendeuka.Isu tinokwanisa kubata chero purojekiti chaiyo kubva kune yakagadziriswa zvigadzirwa kugadzira, engineering, uye prototype chivakwa.Isu tinokoshesa kutonga kwemhando, uye kutevedza kwemitemo, izvo zvinotibatsira kuvimbisa kunaka kune zvese zvigadzirwa zvedu.Tine ruzivo rwakakura mukuvaka zvikamu zvevatengi mukudzivirira, semiconductor, maindasitiri emuchadenga nezvimwe.

-

Maitiro e Precision CNC Zvikamu

Zvishandiso zveCNC Machining:

CNC machining inyanzvi uye inodhura-inoshanda kugadzira maitiro.Iyi nzira inowirirana nehuwandu hukuru hwezvinhu.Saka nekudaro, CNC machining inobatsira mhiri kwakasiyana siyana kwemaindasitiri kune akasiyana maapplication.Vagadziri uye machinists vanoshandisa iyi nzira nenzira dzakasiyana.Izvi zvinosanganisira nzira yekugadzira yakananga, nzira yekugadzira isina kunanga, kana yakabatana nemamwe maitiro.

Sezvinei nechero nzira yekugadzira, iyo yakasarudzika mabhenefiti eCNC machining inozivisa rudzi rwemashandisirwo ayo anogona kushandiswa.Nekudaro, mabhenefiti eCNC anodiwa mune ingangoita chero indasitiri.Izvo zvakakodzera kune zvakawanda zvikamu uye zvigadzirwa.Sezvo CNC michina inogona kugadzirisa chero chero mhando yezvinhu, maapplication avo ari pedyo nekusingaperi.

Kubva pane yakananga chikamu kugadzirwa kusvika nekukurumidza prototyping, chinyorwa ichi chinotarisa akasiyana akasimba mashandisirwo eCNC machining.Ngatisvike pazviri!

-

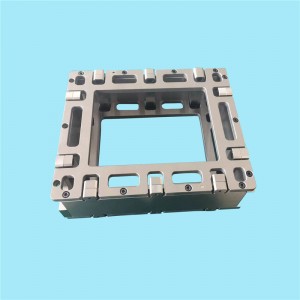

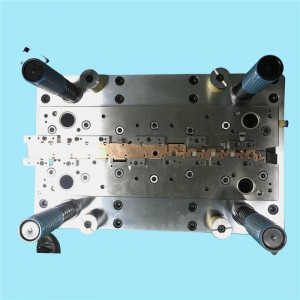

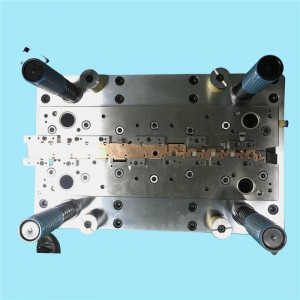

Tsika CNC Precision Machined Molding Zvikamu

Maindasitiri Anoshandisa CNC Machining

Consumer Electronics

CNC machining inobatsirawo mu prototyping uye kugadzirwa kwevatengi zvemagetsi.Izvi zvemagetsi zvinosanganisira malaptops, smartphones, uye zvimwe zvakawanda.Iyo chassis yeApple MacBook, semuenzaniso, inouya kubva kuCNC machining yearuminiyamu yakawedzera uye yobva yaiswa anodized.

Muindasitiri yemagetsi, CNC machining inobatsira kugadzira maPCB, dzimba, jigs, zvigadziriso, uye zvimwe zvikamu.

-

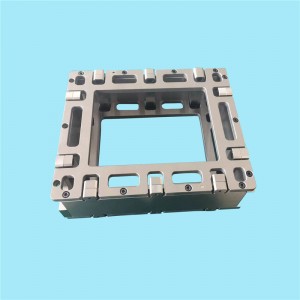

Tsika Yakanyanya Precision Jekiseni Kuumba Zvikamu

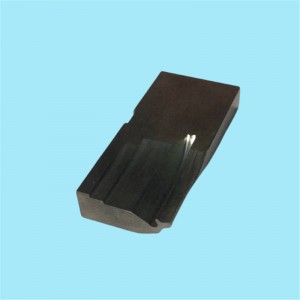

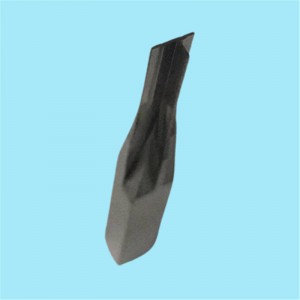

Precision mold zvikamu kuita zvinodiwa

1. Simba uye kuoma

High precision mold uye maturusi emidziyo anowanzo shanda pasi pemamiriro akaoma.Mamwe anowanzo kutakura mutoro mukuru, zvichikonzera kuputsika kwebrittle.Nokudaro, maumbirwo chaiwo anofanira kuva nesimba rakakwirira uye kuoma.Iko kudzivirira mold components kubva pakuputsika kamwe kamwe panguva yekushanda.Uye kuoma kwe mold uye chishandiso zvakanyanya zvinoenderana nekabhoni yemukati, saizi yezviyo, uye microstructure yezvinhu.

2. Kuneta kutyora kuita

Iko kuneta kutsemuka kunoitika nguva dzose kana iyo yakakwirira chaiyo yepurasitiki jekiseni mold zvikamu zviri kushanda.Imhaka yenguva refu mhedzisiro yecyclic stress.Iwo mafomu anosanganisira kuwanda kukanganiswa nesimba diki, kutambanudza, kubata, uye kukotama kuneta kutsemuka.Kazhinji, iyi pfuma yekuumbwa kwetsika uye tooling zvinoenderana nezvinhu izvi.Kufanana nesimba rayo, kuoma, kuomarara, uye zvinosanganisirwa zvirimo muzvinyorwa.

-

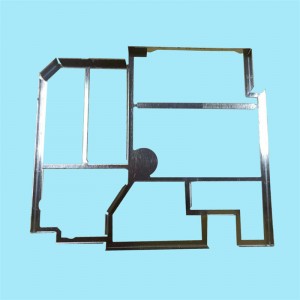

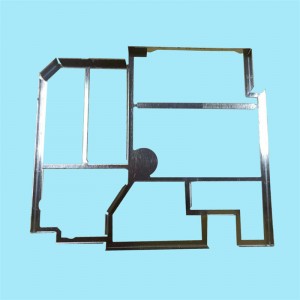

Precision Sheet Metal Uye Stamping Zvikamu

Mhando dzeSheet Metal Stamping Maitiro

Kune akawanda akasiyana simbi stamping maitiro.Imwe neimwe yadzo yakakosha asi semusanganiswa, inogona kuburitsa chero chero geometry inogoneka.Heano akanyanya kupararira sheet simbi stamping maitiro.

Blanking kazhinji ndiyo yekutanga kuvhiya kunoitwa pakati pezvitambi.Inoda chidhindo chekutsikisa chine chibhakera chakapinza.Mashizha esimbi anowanzo kupihwa muhukuru hwakakura se3 × 1,5 m.Zvizhinji zvezvikamu hazvina kukura, saka uchada kucheka chikamu chebepa kune chikamu chako, uye zvingave zvakanaka kuti utore yaunoda contour yechikamu chekupedzisira pano.Saka, kuvhara kunoshandiswa kuti uwane iyo contour yaunoda.Ziva kuti kune dzimwe nzira dzekugadzira simbi simbi isina chinhu senge laser kucheka, plasma kucheka kana mvura jet kucheka.

-

CNC Machining Zvishandiso zveStainless Simbi Zvikamu

Simbi isina tsvina inoshingirira kuita ngura uye ngura, ichiita kuti ive yakakodzera kushandiswa uko zvikamu zvinogona kuratidzwa kune zvikamu kwenguva yakareba.Simbi isina tsvina inowedzerawo ductile uye ductile.JTR inopa akasiyana siyana esimbi isina tsvina alloys, anosanganisira chikafu-chakachengeteka siyana.

Iwo mazana matatu akatevedzana (303, 304, zvichingodaro) ari austenitic Stainless simbi (zvichienderana nekristaro framework) uyewo ndiwo magiredhi anogadzirwa zvakanyanya pasi rese.Austenitic Stainless simbi mamakisi anozivikanwa nekudzikira kwavo kwakanyanya kuramba uye nekusimba kwepamusoro pamusoro pemhando yetembiricha yakakura.Kunze kwekushanda kunotonhorera, haabatike kupisa uye zvakare anowanzo asiri magineti.