Iri gwara rakazara rinoenzanisa makumi maviri neshanu akajairika zvinhu zvinoshandiswa muCNC machining uye inokubatsira kusarudza iyo yakakodzera yekushandisa kwako.

CNC machining inogona kugadzira zvikamu kubva kune chero simbi kana plastiki.Izvi zvazvakadaro, kune huwandu hukuru hwezvinhu zviripo kune zvikamu zvinogadzirwa kuburikidza neCNC milling uye kutendeuka.Kusarudza iyo yakakodzera yekushandisa kwako kunogona kuve kwakaoma, uye kunzwisisa zvakanakira uye mashandisiro akanaka echinhu chimwe nechimwe chiripo kunogona kukosha.

Muchinyorwa chino, isu tinofananidza akajairika CNC zvinhu, maererano nemakanika uye ekupisa zvivakwa, mutengo uye zvakajairwa (uye zvakaringana) zvikumbiro.

Iwe unosarudza sei iyo chaiyo CNC zvinhu?

Paunenge uchigadzira chikamu kuti ive CNC muchina, kusarudza zvinhu zvakanaka kwakakosha.Heano matanho ekutanga atinokurudzira kutevedzera kuti usarudze zvinhu zvakanaka zvezvikamu zvako zvetsika.

Tsanangura izvo zvinodikanwa zvezvinhu: Izvi zvinogona kusanganisira zvemuchina, zvinopisa kana zvimwe zvinhu zvinodiwa, pamwe nemutengo uye kupera kwepasi.Funga nezve mashandisiro auchange uchishandisa zvikamu zvako uye kuti imhando ipi yenzvimbo yavanenge vari.

Ziva zvinhu zvemumiriri: Pinira pasi mashoma emumiriri zvinhu zvinozadzisa zvese (kana zvakawanda) zvezvaunoda dhizaini.

Sarudza iyo yakanyatsokodzera zvinhu: Chibvumirano chinowanzodiwa pano pakati pezviviri kana kupfuura zvezvinodiwa zvekugadzira (semuenzaniso, mashandiro emuchina uye mutengo).

Muchikamu chino, tichatarisa padanho rechipiri.Uchishandisa ruzivo rwuri pazasi, unogona kuona zvinhu zvakanyanyokodzera chikumbiro chako, uchichengeta purojekiti yako pabhajeti.

Ndeapi mazano eHubs ekusarudza zvinhu zveCNC?

Mune matafura ari pazasi, isu tinopfupikisa hunhu hwakakodzera hweakajairika CNC zvinhu, zvakaunganidzwa nekuongorora madheti akapihwa nevagadziri vezvinhu.Isu tinotsemura simbi nemapurasitiki kuita mapoka maviri akasiyana.

Simbi dzinonyanya kushandiswa mumashandisirwo anoda simba rakakwirira, kuoma uye kupikisa kupisa.Mapurasitiki zvinhu zvakareruka zvine huwandu hwakawanda hwezvinhu zvemuviri, zvinowanzo shandiswa kupikisa kwavo kwemakemikari uye kugona kwemagetsi ekudzivirira.

Mukuenzanisa kwedu CNC zvinhu, isu tinotarisa kune simba remagetsi (rinoratidzwa seyakasimba goho simba), machinability (kureruka kwekugadzira kunokanganisa CNC mitengo), mutengo, kuoma (kunyanya simbi) uye kupisa kwekushisa (kunyanya kumapurasitiki).

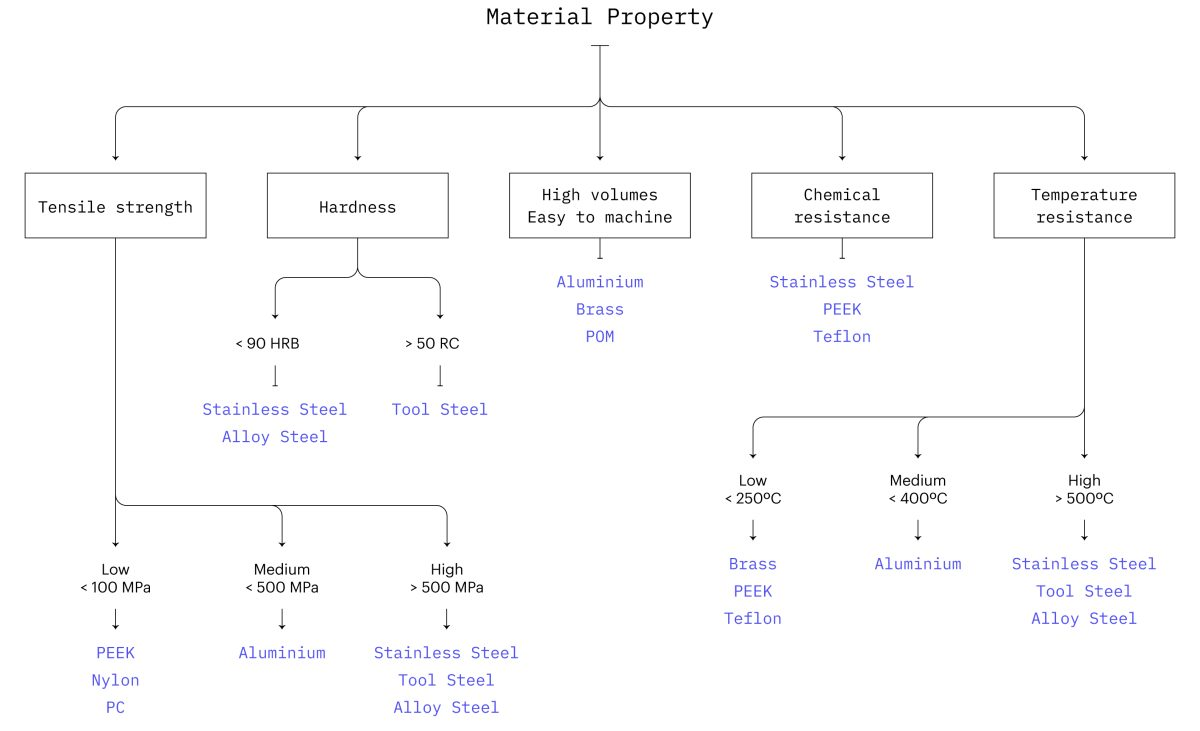

Heino infographic iyo iwe yaunogona kushandisa sechimbichimbi rengedzo yekukurumidza kuona CNC zvinhu zvinoenderana nezvinodiwa zveinjiniya:

Chii chinonzi aluminium?The robust, economical alloy

Chikamu chakagadzirwa neAluminium 6061

Aluminium alloys ane yakanakisa simba-ku-huremu reshiyo, yakakwira yekupisa uye magetsi conductivity uye kuchengetedzwa kwechisikigo kubva mukuora.Iwo ari nyore kumichina uye anodhura-anoshanda muhuwandu, kazhinji achivaita iyo yakanyanya hupfumi sarudzo yekugadzira prototypes uye mamwe marudzi ezvikamu.

Nepo aruminiyamu alloys kazhinji ane simba rakaderera uye kuoma pane simbi, asi anogona kuve anodized, achigadzira yakaoma, inodzivirira layer pamusoro pepamusoro payo.

Ngatiparadzei marudzi akasiyana ealuminium alloys.

❖ Aluminium 6061 ndiyo inonyanya kushandiswa, aruminiyamu-aruminiyamu alloy, ine huremu hwakanaka hwekusimba-kusvika-huremu uye kugona kwakanakisa.

❖ Aluminium 6082 ine maumbirwo akafanana uye zviwanikwa zve6061. Inonyanya kushandiswa muEurope (sezvo inoenderana neBritish Standards).

❖ Aluminium 7075 ndiyo alloy inonyanya kushandiswa munzvimbo dzemuchadenga apo kudzikisa huremu kwakakosha.Iyo ine yakanakisa kuneta zvimiro uye inogona kurapwa kupisa kusvika pakusimba kwepamusoro uye kuoma, zvichiita kuti ifananidzwe nesimbi.

❖ Aluminium 5083 ine simba repamusoro kudarika mamwe akawanda maaruminiyamu alloys uye inorambira kumvura yegungwa.Izvi zvinoita kuti ive yakakwana yekuvaka uye marine application.Iyo zvakare yakanakisa sarudzo yewelding.

Material features:

❖ Kuwanda kwearuminiyamu alloys: 2.65-2.80 g/cm3

❖ Inogona kuve anodized

❖ Non-magnetic

Chii chinonzi Stainless steel?Iyo yakasimba, yakasimba alloy

Chikamu chakagadzirwa kubva Stainless Steel 304

Stainless simbi alloys ane simba rakawanda, yakakwira ductility, yakanakisa kupfeka uye corrosion resistance uye inogona kugadzirwa zviri nyore, kugadzirwa nemichina uye kukwenenzverwa.Zvichienderana nekuumbwa kwavo, vanogona kunge vari (chaizvo) kwete-magnetic kana magineti.

Ngatiparadzei marudzi esimbi isina tsvina yatinopa pachikuva.

❖ Stainless simbi 304 ndiyo inonyanya kuzivikanwa simbi isina tsvina.Iyo ine yakanakisa michina zvivakwa uye yakanaka machinability.Inoshingirira kumamiriro ekunze mazhinji uye corrosive media.

❖ Stainless simbi 316 ndiyo imwe yakajairwa Stainless simbi alloy ine zvakafanana mechanical properties kusvika 304. Iine kukwirira kwecorrosion uye chemical resistance asi, kunyanya kune saline solution (somuenzaniso mvura yegungwa), saka kazhinji zviri nani pakubata nenzvimbo dzakaoma.

❖ Stainless simbi 2205 Duplex ine simba repamusoro-soro (rakapetwa kaviri riya remasimbi akajairwa alloys) uye nekupokana kwakanakisa pakuora.Inoshandiswa munzvimbo dzakanyanyisa, iine akawanda maapplication muOiri & Gasi.

❖ Simbi yeStainless 303 ine kusimba kwakanaka, asi kushomeka kwekuora kana ichienzaniswa ne304. Nekuda kwehunyanzvi hwayo hwekugadzira, inowanzoshandiswa mumhando yepamusoro-soro, sekugadzira nzungu nemabhaudhi emuchadenga.

❖ Simbi isina simbi 17-4 (SAE giredhi 630) ine michina inofananidzwa ne304. Inogona kunaya yakaomeswa kusvika padanho repamusoro (inofananidzwa nesimbi dzemidziyo) uye ine yakanakisa makemikari kuramba, ichiita kuti ive yakakodzera kune yakanyanya-kushanda kwekushandisa, senge mablades ekugadzira emagetsi emhepo.

Material features:

❖ Kuwanda kwehuwandu: 7.7-8.0 g/cm3

❖ Non-magnetic Stainless simbi alloys: 304, 316, 303

❖ Magnetic Stainless simbi alloys: 2205 Duplex, 17-4

Chii chinonzi mild steel?The general chinangwa alloy

Chikamu chakagadzirwa kubva kuMild Steel 1018

Simbi dzakapfavadzinozivikanwawo seyepasi-kabhoni simbi uye ine yakanaka mechanical zvivakwa, machinability yakakura uye yakanaka weldability.Nekuti iwo ane mutengo wakaderera, vagadziri vanoashandisa kune akawanda akajairika chinangwa maapplication, senge jigs uye zvigadziriso.Simbi dzakapfava dzinobatwa nekuora uye kukuvara kwemakemikari.

Ngatiparadzei mhando dzesimbi dzakapfava dziripo pachikuva.

❖ Simbi yakapfava 1018 ndeye-general-use alloy ine yakanaka machinability uye weldability uye kusimba kwakanyanya, kusimba uye kuoma.Ndiyo inonyanya kushandiswa mild steel alloy.

❖ Simbi yakapfava 1045 isimbi yepakati kabhoni ine yakanaka weldability, yakanaka machinability uye kusimba kwepamusoro uye kupikisa kuramba.

❖ Simbi yakapfava A36 isimbi yakajairika ine simbi yakanaka.Yakakodzera kune akasiyana maindasitiri uye ekuvaka zvikumbiro.

Material features:

❖ Kuwanda kwehuwandu: 7.8-7.9 g/cm3

❖ Magnetic

Chii chinonzi alloy steel?Iyo yakasimba, isingapfekeki alloy

Chikamu chakagadzirwa kubva kune alloy simbi

Alloy masimbi ane zvimwe zvinosanganisa zvinhu mukuwedzera kune kabhoni, zvichikonzera kuomarara kwakavandudzika, kuoma, kuneta uye kuramba kupfeka.Zvakafanana nesimbi dzakapfava, alloy simbi inotapukirwa nekuora uye kurwiswa kubva kumakemikari.

❖ Alloy simbi 4140 ine yakanaka yakazara michini zvivakwa, ine simba rakanaka uye kuoma.Iyi alloy yakakodzera kune akawanda maindasitiri maapplication asi haina kukurudzirwa kune welding.

❖ Alloy simbi 4340 inogona kurapwa kupisa kusvika pamwero wepamusoro wesimba uye kuoma, ichichengetedza kusimba kwayo kwakanaka, kupfeka kusamira uye kuneta simba.Iyi alloy inogoneka.

Material features:

❖ Kuwanda kwehuwandu: 7.8-7.9 g/cm3

❖ Magnetic

Chii chinonzi tool steel?Iyo yakasarudzika yakaoma uye inopikisa alloy

Chikamu chakagadzirwa nesimbi yekushandisa

Tool steelsmasimbi alloys ane kuomarara kwakanyanya, kuomarara, abrasion uye kupisa kupisa, chero bedzi ivo vachipfuura.kupisa kurapwa.Iwo anoshandiswa kugadzira maturusi ekugadzira (naizvozvo zita) rakadai sekufa, zvitambi uye mold.

Ngatiparadze masimbi emidziyo atinopa kuHubs.

❖ Simbi yemudziyo D2 isimbi isingapfeki inochengeta kuoma kwayo kusvika patembiricha ye425°C.Inowanzoshandiswa kugadzira midziyo yekucheka uye inofa.

❖ Chishandiso simbi A2 isimbi yakaomeswa nemhepo yakarebesa-chinangwa chine kusimba kwakanaka uye kugadzikana kwechimiro chepamusoro patembiricha dzakakwirira.Inonyanya kushandiswa kugadzira jekiseni molding inofa.

❖ Simbi yemudziyo O1 isimbi yakaomeswa neoiri ine kuomarara kwe65 HRC.Inonyanya kushandiswa kugadzira mapanga nemidziyo yekucheka.

Material features:

❖ Kuwanda kwemhando: 7.8 g/cm3

❖ Kuomarara chaiko: 45-65 HRC

Chii chinonzi brass?Iyo conductive & cosmetic alloy

A Brass C36000 chikamu

Brassisimbi alloy ine yakanaka machinability uye yakanakisa magetsi conductivity, ichiita kuti ive yakanaka kune maapplication anoda yakaderera friction.Iwe unowanzo kuwana zvizorwa zvendarira zvikamu zvinoshandiswa pakuvaka zvinangwa (goridhe rinotsanangura).

Heino brass yatinopa kuHubs.

❖ Brass C36000 chinhu chine simba rakanyanya kusimba uye kusaita ngura.Ndicho chimwe chezvinhu zviri nyore kuchinjika, saka chinowanzo shandiswa kune yakakwira-vhoriyamu maapplication.

Material features:

❖ Kuwanda kwehuwandu: 8.4-8.7 g/cm3

❖ Non-magnetic

Chii chinonzi ABS?Iyo prototyping thermoplastic

Chikamu chakagadzirwa kubva kuABS

ABSndechimwe chezvinhu zvakajairika thermoplastic zvinhu zvinopa yakanaka mekiniki zvivakwa, yakanakisa simba rekuita, yakanyanya kupisa kupisa uye yakanaka machinability.

ABS ine low density, ichiita kuti ive yakanaka kune yakareruka maapplication.CNC machined ABS zvikamu zvinowanzo shandiswa se prototypes isati yawanda-kugadzirwa nekuumbwa kwejekiseni.

Material features:

❖ Kuwanda kwehuwandu: 1.00-1.05 g/cm3

Chii chinonzi naironi?Injiniya thermoplastic

Chikamu chakagadzirwa kubva naironi

Nylon(aka polyamide (PA)) ndeye thermoplastic iyo inowanzo shandiswa kuita mainjiniya maapplication, nekuda kweakanakisa makina zvivakwa, yakanaka yekukanganisa simba uye yakakwira makemikari uye abrasion kuramba.Inotapurirana nemvura nehunyoro.

Nylon 6 uye naironi 66 ndiwo mamakisi anonyanya kushandiswa muCNC machining.

Material features:

❖ Kuwanda kwehuwandu: 1.14 g/cm3

Chii chinonzi polycarbonate?Iyo thermoplastic ine simba rekuita

Chikamu chinogadzirwa kubva ku polycarbonate

Polycarbonate ndeye thermoplastic ine kusimba kwakanyanya, yakanaka machinability uye yakanakisa simba rekuita (zviri nani pane ABS).Kazhinji inopenya, asi inogona kudhayiwa kune akasiyana mavara.Izvi zvinhu zvinoita kuti ive yakanaka kune yakafaranuka yekushandiswa, kusanganisira fluidic zvishandiso kana mota glazing.

Material features:

❖ Kuwanda kwehuwandu: 1.20-1.22 g/cm3

Chii chinonzi POM (Delrin)?Iyo yakanyanya machina CNC plastiki

Chikamu chakagadzirwa kubva kuPOM (Delrin)

POM inowanzozivikanwa nezita rekutengesa Delrin, uye injinjiniya thermoplastic ine yakanyanya machinability pakati pemapurasitiki.

POM (Delrin) kazhinji ndiyo yakanakisa sarudzo kana CNC ichigadzira zvikamu zvepurasitiki zvinoda kunyatsojeka, kuomarara kwepamusoro, kukweshera kwakaderera, kugadzikana kwemhando yepamusoro patembiricha yakakwira uye kunyura kwemvura kwakadzikira.

Material features:

❖ Kuwanda kwehuwandu: 1.40-1.42 g/cm3

Chii chinonzi PTFE (Teflon)?Iyo yakanyanya tembiricha thermoplastic

Chikamu chakagadzirwa kubva kuPTFE

PTFE, inowanzozivikanwa seTeflon, injinjiniya thermoplastic ine yakanakisa kemikari uye inodzivirira kupisa uye yakaderera coefficient yekukweshera kwechero inozivikanwa yakasimba.Ndiyo imwe yemapurasitiki mashoma anogona kutsungirira tembiricha yekushanda iri pamusoro pe200 degrees Celsius uye insulator yemagetsi yakatanhamara.Iyo ine zvakare yakachena mechanical zvivakwa uye inowanzoshandiswa senge lining kana kuisa mugungano.

Material features:

❖ Kuwanda kwehuwandu: 2.2 g/cm3

Chii chinonzi HDPE?Iyo yekunze & pombi thermoplastic

Chikamu chakagadzirwa kubva kuHDPE

High-density polyethylene (HDPE)is thermoplastic ine reshiyo yesimba-kusvika-huremu hwepamusoro, kusimba kwesimba uye kunaka kwemamiriro ekunze.HDPE yakareruka uye inokodzera kushandiswa kwekunze uye pombi.Kufanana neABS, inowanzo shandiswa kugadzira prototypes pamberi peJekiseni Molding.

Material features:

❖ Kuwanda kwehuwandu: 0.93-0.97 g/cm3

Chii chinonzi PEEK?Plastiki kutsiva simbi

Chikamu chakagadzirwa kubva kuPEEK

PEEKndeyepamusoro-inoshanda engineering thermoplastic ine yakanakisa mechaniki zvivakwa, kugadzikana kwemafuta pamusoro pehupamhi hwakakura kwazvo hwekushisa uye kupikisa kwakanyanya kumakemikari mazhinji.

PEEK inowanzo shandiswa kutsiva zvikamu zvesimbi nekuda kwekusimba kwayo-kusvika-uremu reshiyo.Magiredhi ekurapa aripowo, zvichiita kuti PEEK ikwanewo kune biomedical application.

Material features:

❖ Kuwanda kwehuwandu: 1.32 g/cm3

Mibvunzo inowanzo bvunzwa

❖ Ndezvipi zvakanakira CNC machining nesimbi?

Simbi dzakanakira kugadzira zvikumbiro zvinoda simba rakawanda, kuomarara uye / kana kuvimbika kupikisa kune tembiricha yakanyanyisa.

Kwakabva nyaya:https://www.hubs.com/knowledge-hub/?topic=CNC+machining

Nguva yekutumira: May-10-2023